Materials Science

Integrated electronic and atomistic modeling of non-periodic functional oxides

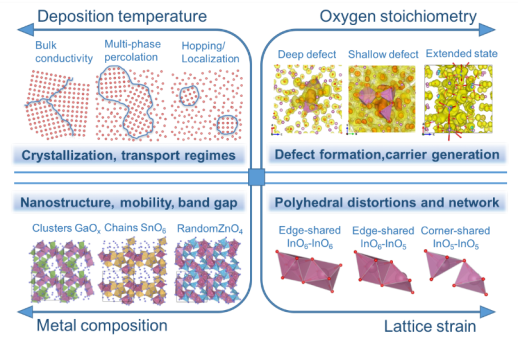

Amorphous oxide semiconductors (AOSs) such as a-In-Sn-O or a-In-Ga-Zn-O, have attracted much attention due to many advantages including low-temperature large-area deposition, flexibility, smooth surfaces and an order of magnitude higher carrier-mobility than that of a-Si:H. Compared to crystalline transparent conducting oxides, the structure of AOSs is extremely sensitive to deposition, stoichiometry, and composition, giving rise to a wider range of tunable properties (optical absorption/transmission, work function, carriers and mobility) and enabling novel functionalities. Here, multi-scale molecular-dynamics simulations are integrated with density-functional calculations to establish comprehensive growth-structure-property relationships in prototype AOSs and to derive practical design principles for next-generation AOSs materials and AOS-based devices.

Principal Investigator

Julia Medvedeva

Professor

573-341-4789 | juliaem@mst.edu |

114 Physics building

Density-functional methods. Ab-initio molecular dynamics. Structural, electronic, magnetic, optical, and mechanical properties of solids from first principles. Transparent conducting oxides; amorphous oxide semiconductors; advanced steels; dilute magnetic semiconductors; strongly-correlated materials.

Integrated atomistic and phase-field modeling of solidification of metals

During solidification of metals several complex and interconnected phenomena occur such as the crystal nucleation from the melt, the formation of stable and metastable phases, grain formation and growth, phase transformations, nano- and microsegregations, and defect formations. Solidification occurs in several manufacturing processes, including casting, welding and laser additive manufacturing, and it is essential to predict and control the nano- and microstructures and defects that develop during solidification, because they control the properties of the metallic products.

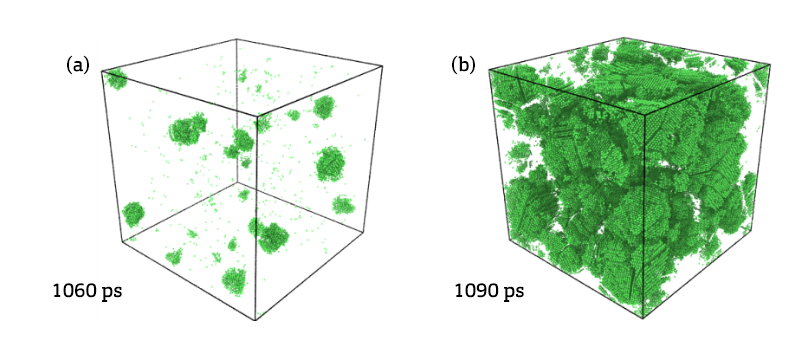

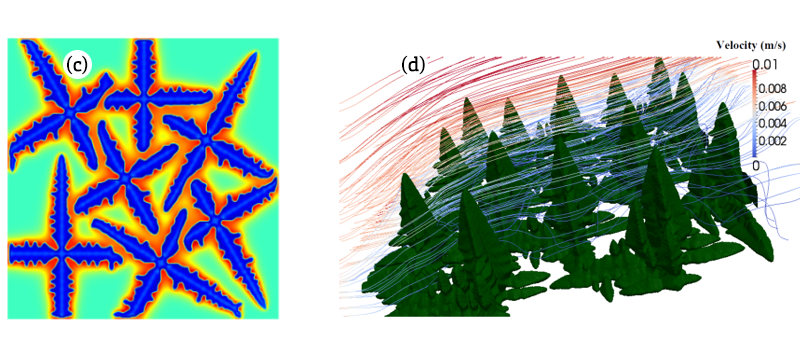

- (a) and (b) time evolution of a 3D MD simulation box (~1 M atoms) in formation of crystals in an Al alloy. Solidification microstructures of Al-3%Cu predicted by (c) a 2D phase-field simulation, and (c) a 3D phase-field simulation with melt flow velocity streamlines -

Principal Investigator

Mohsen Asle Zaeem

Couch Assistant Professor

573-341-7184 | zaeem@mst.edu |

B49 McNutt Hall

Phase field modeling of nano/microstructural evolution, in particular during solidification, recrystallization, phase transformation, and oxidation; multiscale/multiphysics modeling; finite element method; severe plastic deformation.